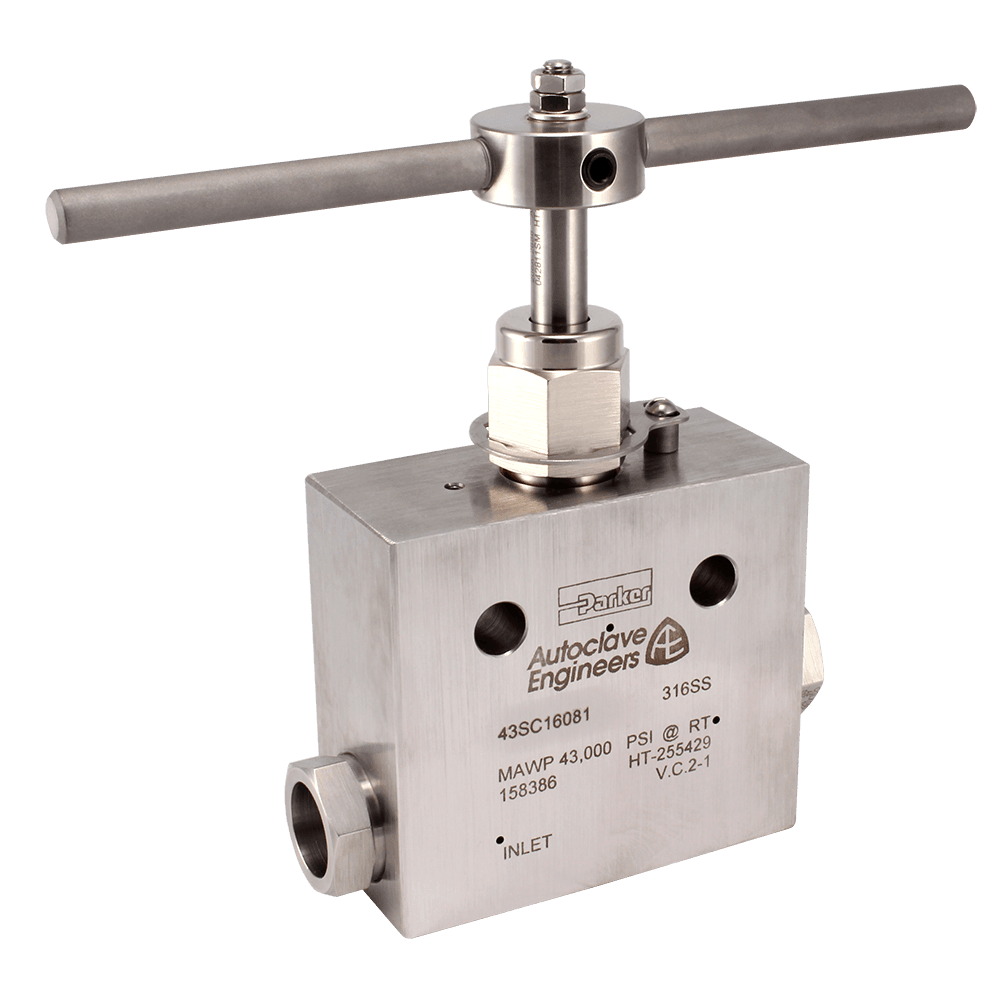

Needle Valve, High Pressure - SC Series

Parker Autoclave's SC Series needle valves are a non-rotating rising stem design, with working pressures to 43,000 psi (2965 bar). These valves are available in 316 Stainless Steel and utilize the proven autoclave cone and thread connection.

4 références disponibles

| Référence | Type de tige | Pression maximale (psig) | Type de corps | Style de raccordement | Matériau du corps |

|---|---|---|---|---|---|

30SC16071 | VEE | 30,000 | 2 Way Straight | 1" Cone and Thread | 316 Stainless Steel |

30SC16072 | VEE | 30,000 | 2-Way Angle | 1" Cone and Thread | 316 Stainless Steel |

30SC16081 | Reg | 30,000 | 2 Way Straight | 1" Cone and Thread | 316 Stainless Steel |

30SC16082 | Reg | 30,000 | 2-Way Angle | 1" Cone and Thread | 316 Stainless Steel |

Description

Parker Autoclave's SC Series needle valves are a non-rotating rising stem design, working pressures to 43,000 psi (2965 bar). Tubing sizes are 1" for this high pressure valve. Tubing connections utilizes Parker Autoclave cone and thread design. Standard high pressure needle valves with PTFE packing may

be operated from 0°F (-17.8°C) to 450°F (232°C). High temperature packing is available for service from -423°F (-252°C) to 1200°F (649°C)

Along with their many features these valves provide dependable and trouble free service in wide variety of applications.

Markets:

• Oil and Gas

• Petrochemical

• Chemical

Features/Benefits:

• Tubing sizes from 1/4” to 1”.

• Non-rotating stem prevents stem/seat galling.

• Rising stem/barstock body design.

• Metal-to-metal seating achieves bubble-tight shut-off, longer stem/seat life in abrasive flow, greater durability for repeated on/off cycles and excellent corrosion resistance.

• For dependable stem and body sealing 30SC, 43SC and 30VM valves are furnished with PTFE encapsulated packing; the 40VM and 60VM valves feature nylon/leather packing below threads.

• Stem sleeve and packing gland materials have been selected to achieve extended thread cycle life and reduced handle torque.

• Choice of Vee or Regulating stem tips.

Applications:

• Large Diameter Tubing Lines

• High Pressure Skid Panels

• Chemical Injection

• High Pressure Fluid Handling Systems